Browse Through Our Collection of Industrial Equipment

Welcome to Eddington Industries’ Product Page. Please Click on a Product Picture to Get More Information!

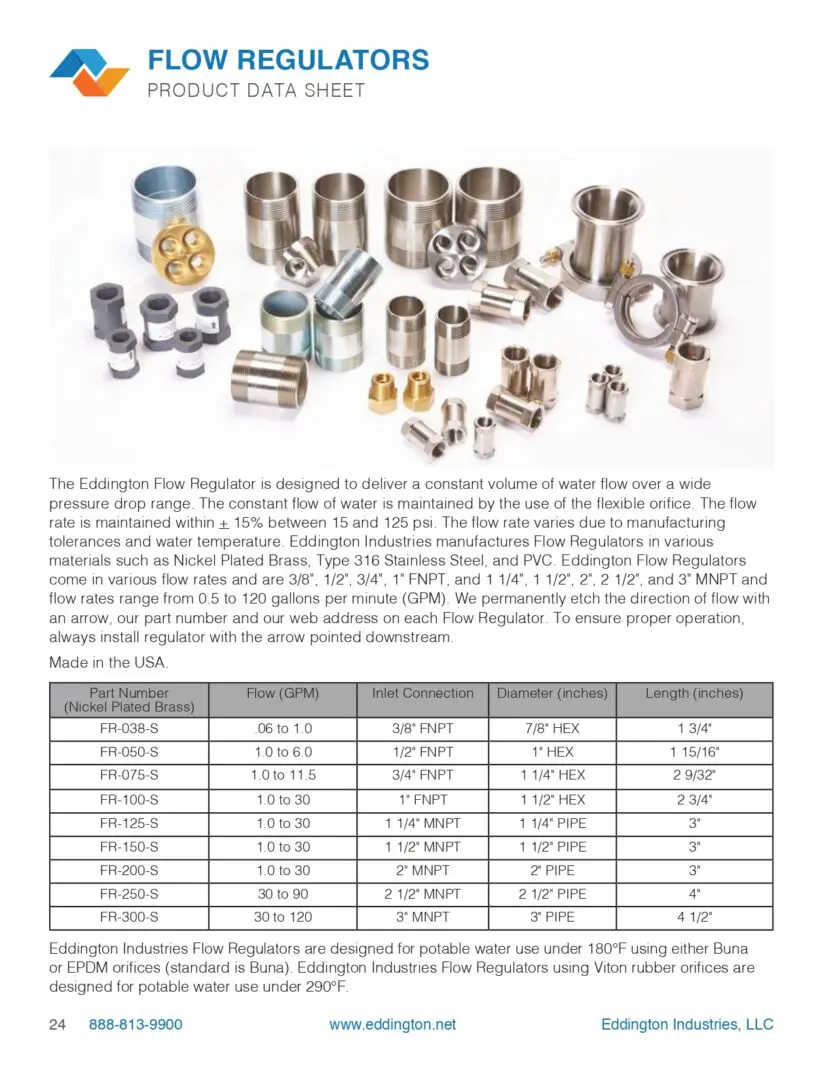

All / Check Valves / Corporation Stop and Nozzle Assemblies / Corrosion Coupon Rack / Corrosion Test Coupons / Coupon By-Pass System / Coupon Holders / Dole Valve / Embrittlement Detector / Featured / Flow Regulators / Glycol Feeders / Injection Quills / Pressure Valve / Sample Cooler / Sight Gauges / Steam Sampling Nozzle

Coupon By-Pass System – 4000 Series

Corrosion Test Coupons

STEAM SAMPLING NOZZLE

Click Here To View Our Product Data Sheet

FEATURES:

Steam sampling nozzles are based on ASTM D-1066-82

Nondestructive testing, welds, heat treatment, construction, materials and design must be in accordance with all applicable codes

The line and sampling nozzle should be the same material of construction

When single port nozzles cannot be installed in superheated supply tubes, multiport sampling nozzle is recommended for saturated or super heated steam in larger tubes or lines

Made in the USA

MANUAL GLYCOL FEEDER GL50-M-E

Click Here To View Our Product Data Sheet

Model # GL-50-M-E is a manual unit which means that you simply plug the unit into an outlet and the pump comes on and remains on until the unit is unplugged. It comes completely assembled and ready to use.

Tank:

55 gallon polyethylene tank with a PE cover. The Tank is fully supported and restrained by a carbon steel bottom mount stand. Stand painted with enamel paint.

Gear pump:

1/2 HP gear pump provides steady and even flow against pressure with an internal pressure relief bypass valve. Pump suction plumbing includes PVC drain valve, flexible tubing and Y-strainer. Pump discharge tubing includes brass check valve

Electrical:

115 Volt AC power cord, 8’ L

Piping:

Pump suction plumbing includes 1/2″ Sch 80 PVC piping with a PVC drain valve, flexible tubing with bronze Y-strainer. Pump discharge tubing includes 1/2″ Sch 40 brass piping with a brass check valve.

Dimensions:

23”L x 23”W x 62”H

System Connection:

3/4” Brass FNPT

Made in the USA.

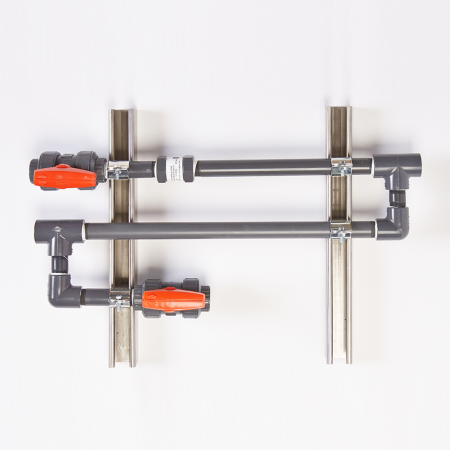

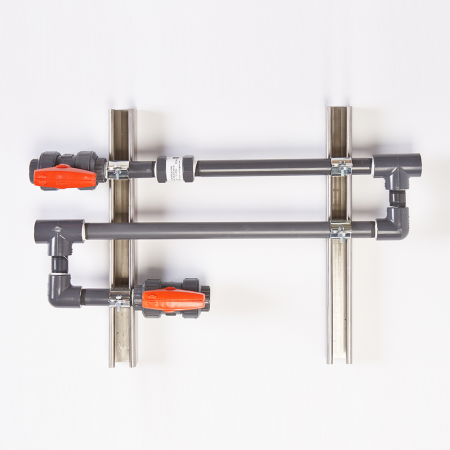

COUPON BY-PASS SYSTEM – 4000 SERIES

Click Here To View Our Product Data Sheet

Our standard 4000 Series Corrosion Test Coupon By-Pass Systems are available with one to six coupon holders and have both inlet and outlet isolation ball valves. They are available in a choice of four materials: Sch 80 PVC, suitable for most applications; CPVC, for applications requiring moderately higher temperature; Carbon Steel and Stainless Steel for high-temperature

applications. The PVC and CPVC bypass systems are mounted on a high density polyethylene mounting board.

All piping and valves for the bypass are to be either ¾ or 1 inch.

Made in the USA.

Applications:

- Cooling Towers

- Chillers

- Boilers

- Heat Exchangers

- Condenser Units

Construction Materials Available:

- Black iron

- CPVC

- PVC

- 304 stainless steel

- 316 stainless steel

Options:

- Custom configurations and materials

- Back flow check valves

- Flow control valves

- Flow indicators

- Y-strainers

- Test sample valves

1. Test specimens must be handled carefully to avoid coating with natural oil from the skin, thread compound or any similar material.

2. When removed, each specimen is to be carefully disconnected from the holder and then immediately dried with hot air or by sponging with a paper towel. Do not clean or remove any residue that may be on the coupon. Insert the specimen in the original envelope or wrap in cellophane. Enclose the test coupon data card showing company name, locations of the bypass, specimen number, date of installation and date of removal. Promptly mail to the Eddington Group for analysis.

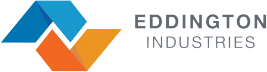

RETRACTABLE COUPON HOLDER

Click Here To View Our Product Data Sheet

Simple Retrieval System (up to 300 psi) for removing corrosion test coupons.

Features:

- Standard connection ¾” MNPT

- Available with ½” to 2” NPT threaded or flange connections

- Safety chain

- Welded safety collar

- Made in the USA

Specifications:

- Process Connection: ¾” or 1” MNPT (standard)

Materials:

- Wetted Parts: Type 316 stainless steel

- Packing: Graphite (maximum temperature – 700 °F)

* Custom Retractable Holder available upon request.

SIGHT GAUGES

Click Here To View Our Product Data Sheet

“Liquid level Gauge”:

Used to calibrate chemical injection systems. The gauge provides a visual means for checking the contents of a bulk tank and a means for checking the injection rate of a chemical metering pump. To gauge is designed to operate in low to medium pressure applications up to 500 psig.

One Minute Test:

Isolate the chemical in the tank from the gauge. The scale on the left side is for the gauge volume and the scale on the right will read the flow rate of the pump; i.e. gallon per Hour (GPH). Keeping the

isolation valve closed and noting the number of marks the fluid

passes in one minute will give the actual chemical pump rate.

Gauge Features:

- Teflon compression ferrule used to isolate the glass tube from the chamber

- Rugged armored gauge construction protects sight glass from mechanical impact

- Custom scales for tank volume or other calibrations are available

- Armored frame and poly carbonate shield protect operator

- ½” NPT and flange connections standard

- Standard sight tube is 5/8” O.D. glass.

- Made in the USA

Gauge Specifications:

- Process Connection: ½” MNPT

Housing Material:

- C = Zinc Plated Carbon Steel

- A = All wetted parts 316 Stainless Steel with 304 Stainless Steel Frame

- W = All wetted parts 316 Stainless Steel with Zinc Plated Carbon Steel Frame

- PC = All wetted parts PVC with Carbon Steel Frame

- PS = All wetted parts PVC with Stainless Steel Frame

Sight Tube Material:

- 5/8” O.D. Standard Glass

- *Other sight tube materials available. Consult factory for options

EMBRITTLEMENT DETECTOR

Click Here To See Our Product Data Sheet

The Embrittlement Detector is designed to simulate conditions in a boiler tube seam. By bringing boiler water in contact with the stressed specimen, the detector determines if the water causes embrittlement cracking.

Carbon steel replacement specimens available.

Features:

• Assessing the tendency of industrial boiler waters to cause embrittlement • Material construction A108 C1018

• Made in the USA

BACK PRESSURE VALVES

Click Here To See Our Product Data Sheet

Back pressure valves using diaphragms are designed to protect pumping systems from over pressure damage caused by defective equipment or blockage in the pump system line.

Eddington Industries is a manufacturer of high quality back pressure valves made from a variety of different materials to suit most needs. In most cases we are able to ship within 2 – 3 days after receipt of order because of our extensive inventory.

FEATURES OF EDDINGTON BACK PRESSURE VALVES:

- Reliability and low cost.

- Adjustable from 15 to 150 psi.

- 2 port (standard) or 3 port (with gauge).

- Viton diaphragm standard (others available).

- Full range of chemically resistant wetted materials.

- Sizes from ¼” to 1” depending on model.

Diaphragm back pressure valves operate when the pressure in the pumping system exceeds the preset pressure of the valve. The diaphragm is held against the valve seat by an internal spring. When the preset pressure is exceeded the diaphragm is forced up and the system fluid flows out the relief port, back to the system fluid tank or to the suction side of the pump. The valves are pre-set at 40 psi; however they are field adjustable from 10 to 150 psi, (optional 350 psi) via the adjustment screw. The relief valve should be set approximately 15 psi higher than the system pressure. Installation should be made as close to the pump as possible.

Eddington Industries performs a pressure test on every back pressure relief valve prior to shipping.

This ensures the unit will operate leak-free and to the specified pressure ratings.

These Eddington Industries back pressure valves come standard without a gauge port or gauge. When ordering please specify if a gauge port and/or gauge is required.

PRESSURE RANGE:

5 – 150 psi (50 – 350 psi available on metal valves).

AVAILABLE DIAPHRAGM MATERIAL:

Viton – Standard.

EPDM – Upon Request.

Eddington Industries is a proud member of

GLYCOL FEEDER GL-50-E

Click Here To See Our Product Data Sheet

For more technical information please refer to our GL-50-E Submittal 2017 Sheet.

The Eddington Industries Glycol Feeder has been totally redesigned by our engineers and licensed electrician to provide our customers with a quality product at a much less expensive price. We first introduced our current design in 2014 at the AWT show in Fort Worth, Texas. Since that time our glycol feeder has been accepted by a large amount of members and continues to be a hot item in the industry.

Our glycol feeder comes fully assembled and ready to use. Every unit is tested for proper operation and leaks before it leaves our facility. For shipping purposes, the Eddington Industries Glycol Feeder is mounted to the center of a pallet and wrapped with bubble wrap and then with shrink wrap. This gives a visual to the freight carrier and helps prevent damage in shipping.

Gear pump: 1/3 HP and 1/2 HP motors with bronze gear pump

Provides steady and even flow against pressure with an internal Eddington pressure relief bypass valve. Pump suction plumbing includes PVC drain valve, PVC ball valve, brass Y-strainer, and flexible tubing. Pump discharge plumbing includes brass check valve, brass tubing , pressure switch and Eddington back flow pressure relief valve with a 3/4″ FNPT system connection.

Tank: 55 gallon polyethylene tank with a PE cover. Tank is fully supported and restrained by a painted carbon steel bottom mount stand.

Control panel: The NEMA 4X control panel comes standard with 115V power cord. The control panel includes 3 position(Hand-Off-Auto) switch, red “Low Level” and green “Main Power” lights, and 15 amp fuse. It also comes standard with LED (cool to the touch) indicator lights. The control panel is on a steel painted cross member for rigidity.

Low level switch: Polypropylene side entering low level switch with 10 AMP relay

Pressure switch: 5 – 65 psi – 1/4” NPT pressure switch

Pressure relief valve: 5-150 PSI (Manufactured by Eddington Industries)

System connection: 3/4” Brass FNPT

The Eddington Industries Glycol Feeder has a list of options available, please View PDF for details. For more technical information please refer to our GL-50-E Submittal 2017 Sheet.

Made in USA.

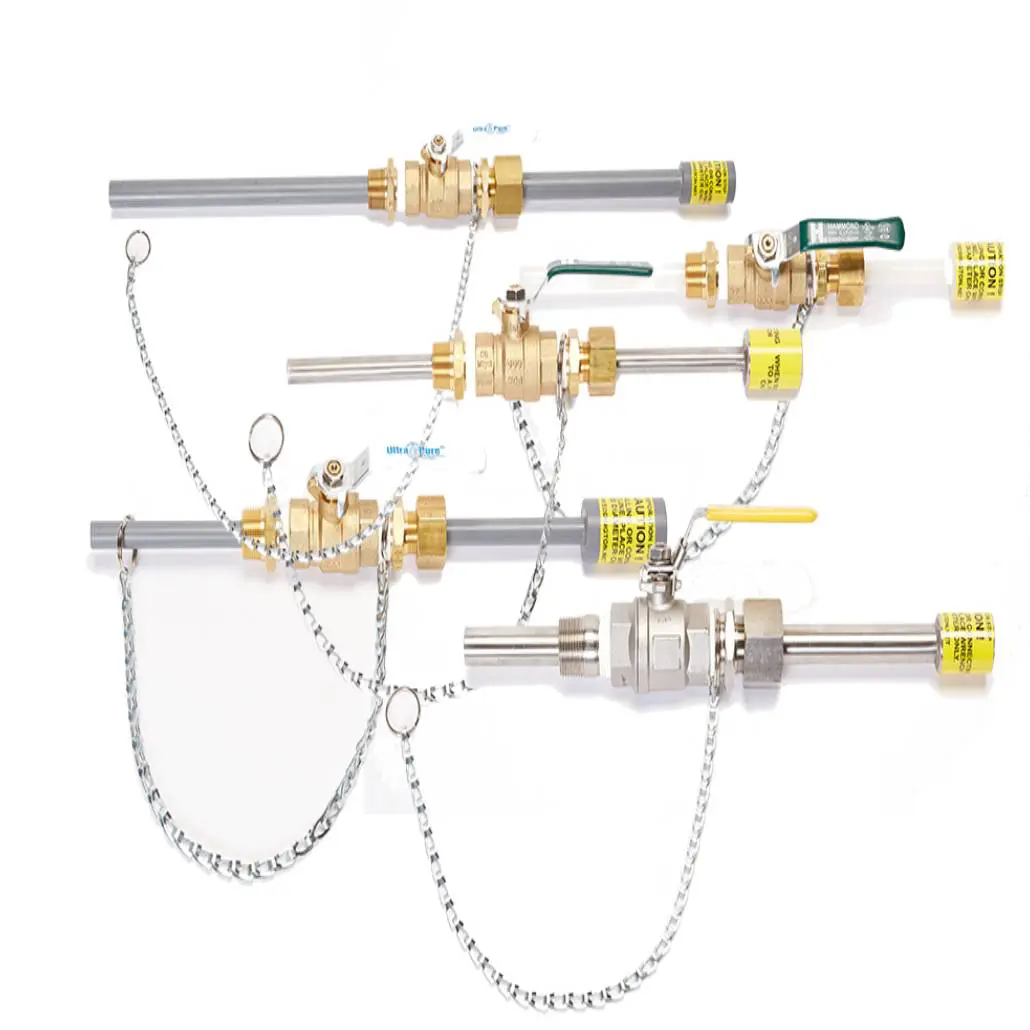

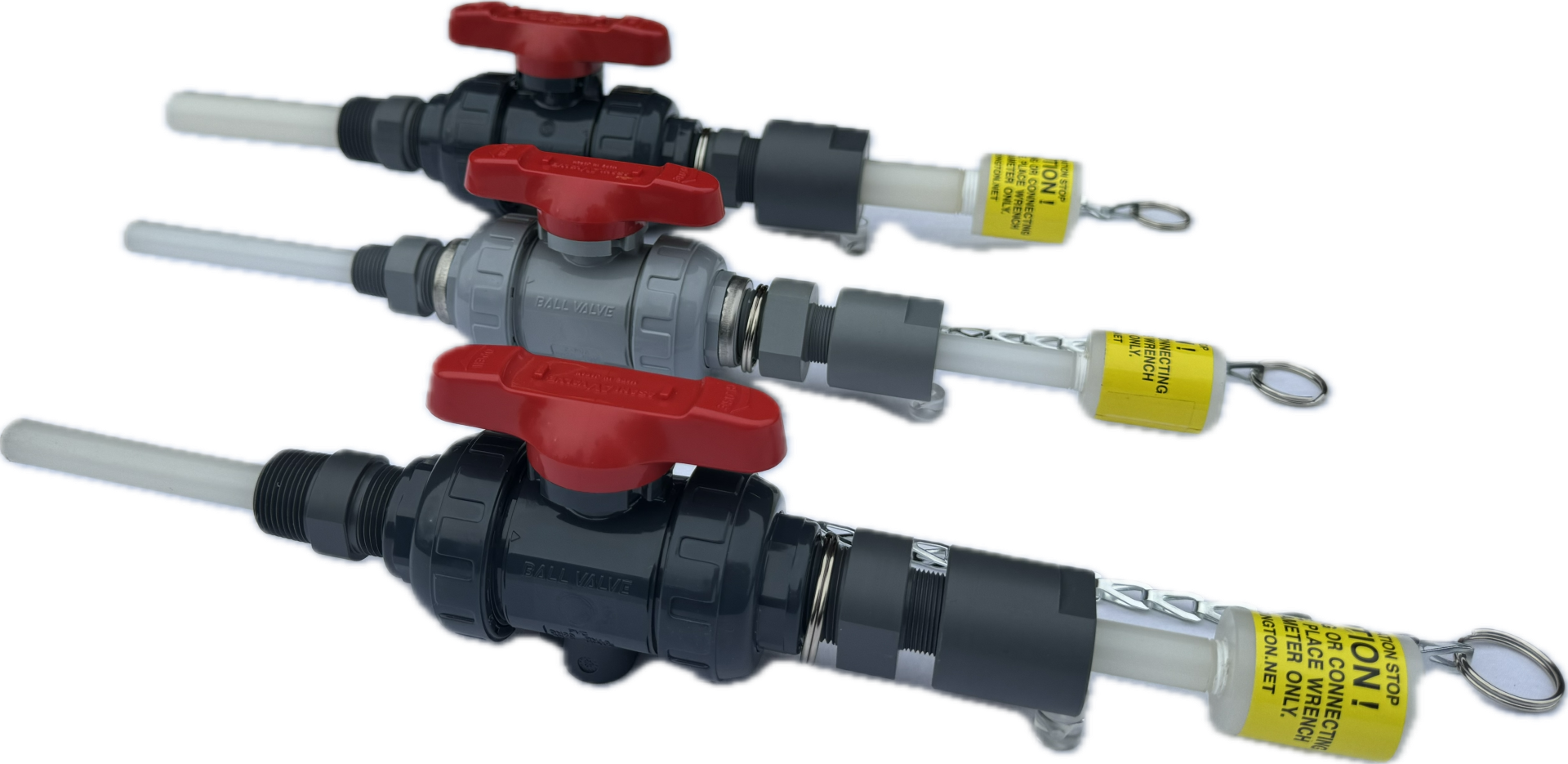

COUPON HOLDERS FOR CORROSION MONITORING

Click Here To See Our Product Data Sheet

Eddington Industries offers a full line of coupon holders for the purpose of corrosion monitoring.

Eddington manufactures coupon holders to fit any corrosion coupon made by most manufacturers.

A variety of manufactured stems and hardware are available.

We offer a full line and inventory of both 3/4″ and 1″ coupon holders.

Corrosion test coupon holders have three components, the pipe plug, the stem, and the hardware to hold the coupon on.

Pipe plugs come standard in PVC, Stainless Steel, and Carbon Steel in both 3/4″ MNPT and 1″ MNPT.

Each coupon holder comes with hardware to mount the coupon. Our hardware choices are Stainless Steel, Nylon, and Teflon.

2205 Series – 3/4″ Steel Coupon Holders (available with Steel, Nylon, or Teflon Stems).

2405 Series – 3/4″ PVC Coupon Holders (available with PVC, Nylon, or Teflon stems).

2505 Series – 3/4″ Stainless Steel Coupon Holders (available with Stainless Steel or Teflon stems).

2215 Series – 1″ Steel Coupon Holders (available with Steel, Nylon, or Teflon stems).

2415 Series – 1″ PVC Coupon Holders (available with PVC, Nylon, or Teflon stems).

2515 Series – 1″ Stainless Coupon Holders (available with Stainless Steel or Teflon stems).

270600 – Retractable Coupon Holder, Type 316 SS, 3/4″ MNPT Process Connection, Teflon Hardware – 18″ Max insertion length.

271600 – Retractable Coupon Holder, Type 316 SS, 1″ MNPT Process Connection, Teflon Hardware – 18″ Max insertion length.

Standard coupon holder lengths are 3″ & 6″ long, special lengths are available upon request.

Different stem material available on request.

Made in the USA.

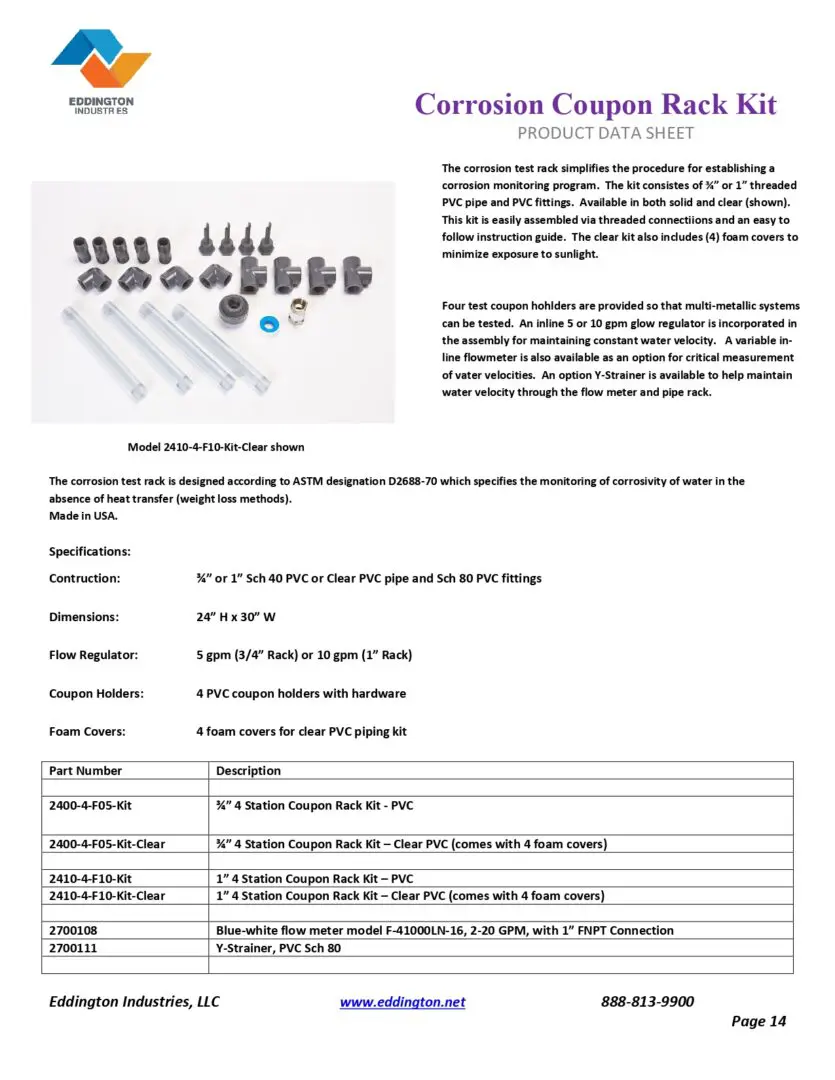

CORROSION COUPON RACK - 2000 SERIES

EDDINGTON COUPON RACK

Click Here To See Our Product Data Sheet

The coupon rack simplifies the procedure for establishing a corrosion monitoring program. This unit is pre-assembled and consists of threaded PVC, black iron or stainless steel pipe and fittings.

One to six test sites can be provided so that the multi-metallic systems can be tested. A variable in-line flow regulator can be incorporated into the assembly for critical measurement of water velocities. An optional Y-strainer is available to help maintain water velocity through the flow meter and pipe rack.

The corrosion test rack is designed according to ASTM designation D2688-70 which specifies the monitoring of corrosivity of water in the absence of heat transfer (weight loss methods).

Sizes:

- 1″ Sch 80 PVC Pipe.

- 1″ Sch 40 Black Iron Pipe

- 1″ Sch 40 Type 304 Stainless Steel

- 3/4″ Sch 80 PVC Pipe

- 3/4″ Sch 40 Black Iron Pipe

- 3/4″ Sch 40 Type 304 Stainless Steel

Options:

- 1-6 station coupon holders (typical rack assemblies are 2, 3, 4, and 6 stations).

- Available with or without mounting options (see below).

- High pressure (300 psi) coupon rack available (2600 series).

- Made in the USA.

Mounting Options

- Polyethylene Board

- Strut Mount – **Recommended – Strut Mount gives you a less expensive and much more sturdy mounting option. Coupon Racks cannot twist during shipping and are very easy to hang.

Construction Materials Available:

- Black iron.

- CPVC.

- PVC.

- 304 stainless steel.

- 316 stainless steel.

Specifications:

- Construction: Threaded PVC, black iron, or type 304 stainless steel pipe and fittings.

- Dimensions: 24” H x 30” W.

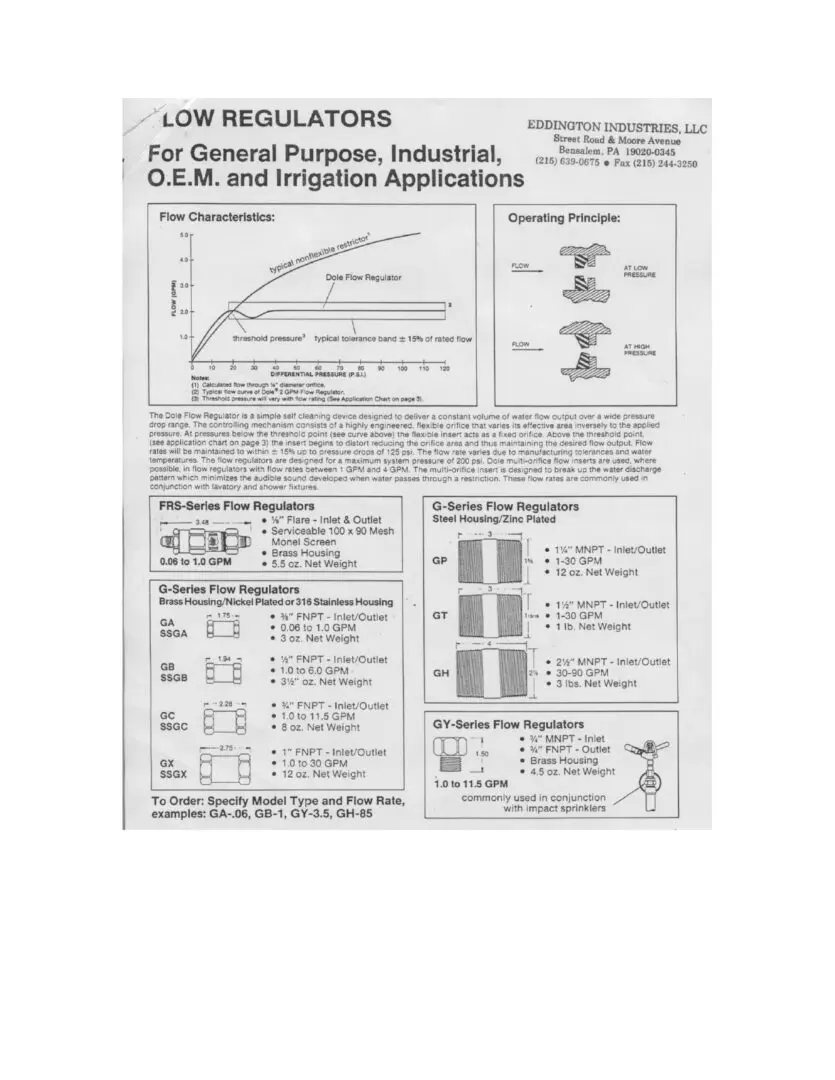

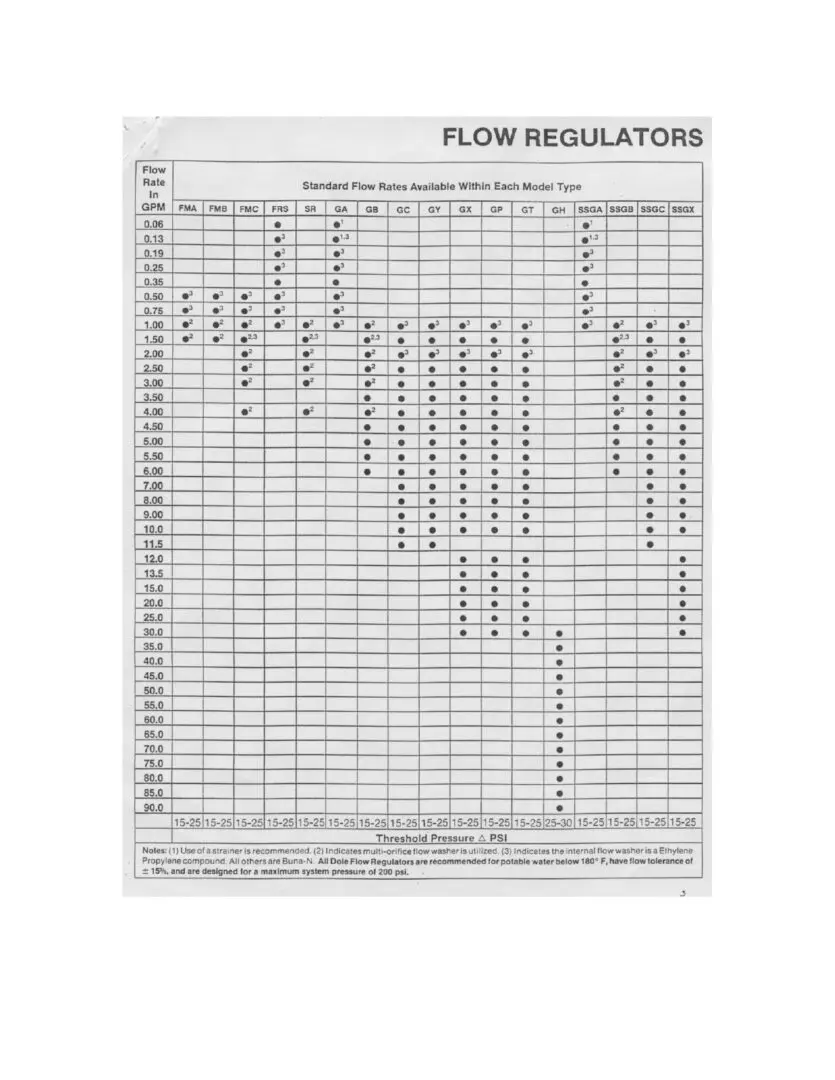

- Lead Free, Nickel Plated Flow regulator: ¾”- 5 GPM (standard), 1”- 10 GPM (standard).

- Flow meter: Optional 2 – 20 GPM flow meter.

- Y strainer: Optional.

- Maximum allowable temperatures @ pressure.

80° —> 280 psi.

100° —> 198 psi.

120° —> 128 psi.

>140° —> Not recommended.

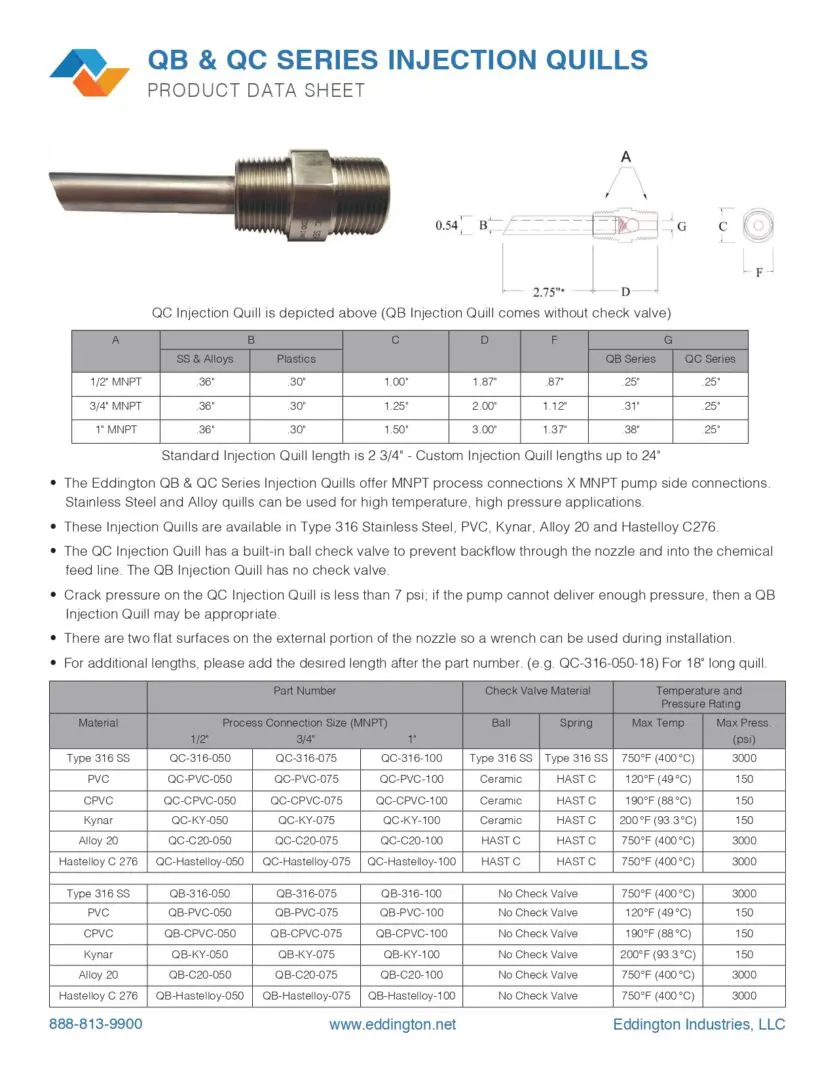

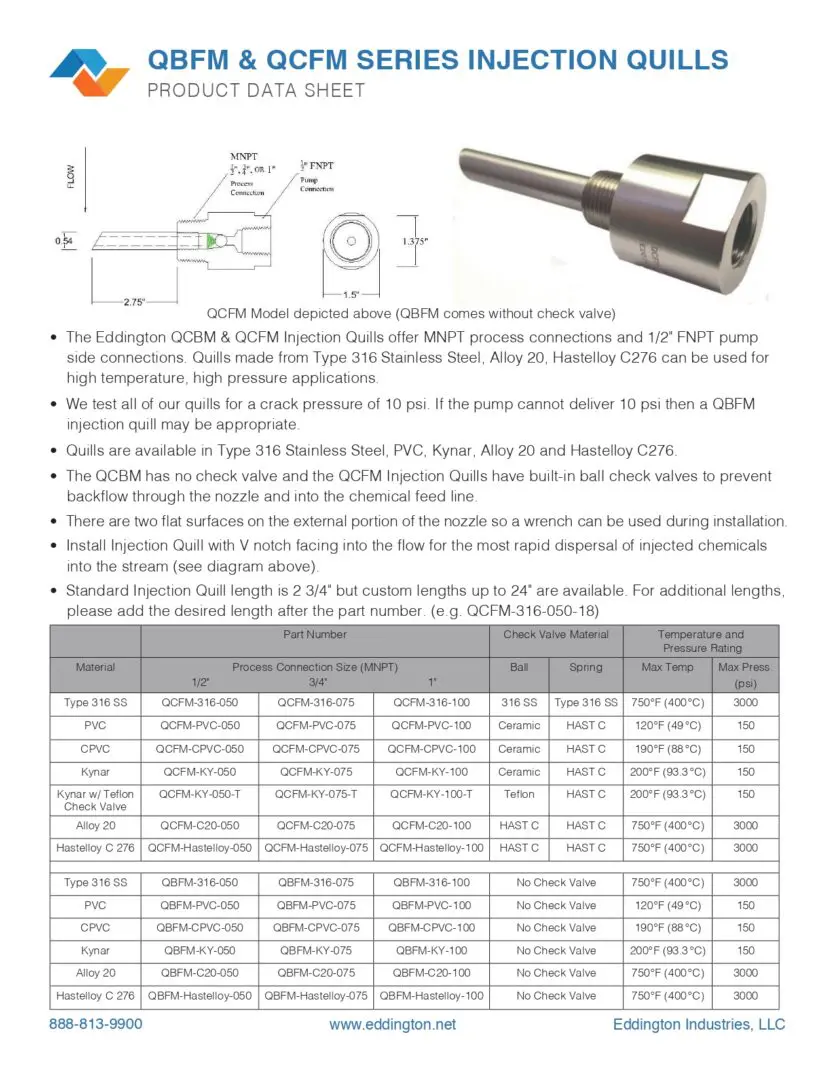

QCC Injection

Quill Assembly

Click Here To See Our Product Data Sheet

Depicted: QCC Series, 1/2" Injection Quill Assembly, 1/2" NPT, type 316 SS with:

- 1/2" MNPT Process Connection

- 1/2" FNPT Pump Connection

- 1/2" Ball Valve with Teflon Seals

- 1/2" Check Valve with type 316 SS Ball & Spring

- P/N: QCC-050-316

Note: Unit comes assembled

*Standard Injection quill Length is 2 ¾” – Custom Injection Quill Lengths up to 24”

- Typical Application: Used in applications where shutting down a system to maintain the metering pump and/or check

valve is not an option. - Every quill assembly comes standard with a 2 ¾” Type 316 SS QB injection quill (no internal check), Type 316 SS Ball

Valve with Teflon Seals and our CVFM Type 316 Stainless Steel Check Valve (Type 316 SS Ball and Spring). - The Eddington QCC Injection Quills offer MNPT process connections X FNPT pump side connections.

- The QCC Injection Quill comes with an Eddington Type 316 SS CVFM ball check valve to prevent backflow through the

nozzle and into the chemical feed line. - Crack pressure on the QCC Injection Quill is 15 psi.

- There are two flat surfaces on the external portion of the injection nozzle so a wrench can be used during installation.

- Standard injection quill length is 2 ¾” but custom lengths up to 24” are available. For additional lengths please add

the desired length after the part number (e.g. QCC-316-050-18).

Other materials available upon request

| Part Numbers | Process Connection | Pump Connection | Check Valve Material | Temperature Deg F (C ) | Maximum Pressure (psi ) | |

|---|---|---|---|---|---|---|

| Ball | Spring | |||||

| QCC -316-050 | ½" | ½" | 316SS | 316SS | 475F (276) | 2000 |

| QCC -316-075 | 3/4" | 1/2" | 316SS | 316SS | 475F (276) | 2000 |

| QCC -316-100 | 1" | ½" | 316SS | 316SS | 475F (276) | 2000 |

Corrosion Test Coupons

Applications:

- To provide a basis for estimating service life of process equipment

- To provide an insight into corrosion mechanics

- To compare resistance of one alloy to another

- As a quality control test for a given heat of alloy

- Pre-weighing and Post-weighing of coupons available upon request

- Made in USA

Finishes:

Coupons can be furnished with a variety of finishes depending on your particular application. Some of the typical finishes available are defined below.

Mill: Finish as produced from mill

Glass Bead: Blasted with fine glass beads to remove mill scale

120 Grit: Fine finish commonly used in corrosion tests, such as pitting studies where smooth surface finish is desired.

Finishes up to 600 grit (extremely fine) can be provided.

| Part Number | Material | Hole Size |

| 100100 | C101D Steel | 3/16” |

| 100200 | Copper, CDA110 | 3/16” |

| 100300 | Admiralty Brass | 3/16” |

| 100400 | Galvanized Steel | 3/16” |

| 100500 | Copper Nickel, 90/10 | 3/16” |

| 100600 | Aluminum, 7075-T6 | 3/16” |

| 100700 | Type 304 Stainless Steel | 3/16” |

| 100800 | Type 316 Stainless Steel | 3/16” |

| 100900 | Mesh bio Film | 3/16” |

| 101000 | Deposition/scale coupon Steel C1010 | 3/16” |

| 3/16” |

Our team of engineers and machinists is dedicated to meeting the highest standards in manufacturing. As a family-run company, we take particular pride in the quality of our design and work. Through quality control standards and a dedication to excellence, we strive every day to reach a new level of quality and value for our customers.